DR JOHNSON IS HIRING

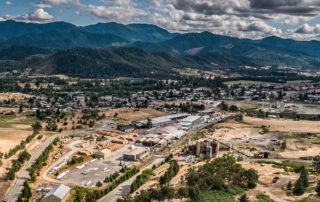

DR JOHNSON IS HIRING!! DR Johnson is looking for hardworking and reliable members to join our team. Available positions include Entry-Level Labor, Chain Pullers, Beam Finisher, Finger Jointer Operator, Saw Filer, Millwrights, Oiler, Planer Feeder, Apprentice Planerman, Graders, Grader Trainee, Sawmill Marker Trainee, and Packaging Plant Operator. Positions available at: DR Johnson Lumber & DR Johnson Wood Innovations located in Riddle, Oregon; Umpqua Lumber Company located in Dillard, Oregon (right off of I5) If you want to join a great team with exceptional benefits, click on the link below to fill out your application. Your application can be submitted in person at 1991 Pruner Road in Riddle, Oregon; or