NOW SELLING CLT MACHINERY

Founded in 1967, DR Johnson Wood Innovations, originally named Riddle Laminators, is a second-generation, family-owned engineered wood products manufacturer located in Riddle, Oregon- the heart of Oregon’s Timber country. For over 53 years, DR Johnson has been producing quality custom glued-laminated beams. In 2015, DR Johnson added a new product, cross-laminated timber, and was the first manufacturer in the United States to meet the requirements of the Standard for Performance-Rated Cross-Laminated Timbers. DR Johnson’s top of the line equipment is now for sale, which consists of the CLT Press, CNC, Baghouse, and the CLT Sander. The whole system was installed into a building that was approximately 32,000 sf. The plant had additional free working space, as well as storage space.

Equipment For Sale:

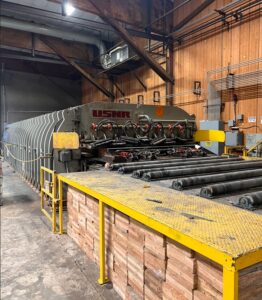

CLT PRESS

- Breakdown hoist and chains for transverse boards

- Assembly plate

- 10’ x 42’ USNR Pneumatic press

- Roll cases to hold panels at infeed and outfeed

- Hydraulic pump & jacks for side pressure

- Electrical components for press.

- Various spare parts – chain, bags, gears, etc.

CNC

- Hundegger PBA D – Machine #7091

- Large format gantry CNC

- Utilizes circular saw, chainsaw, two milling heads, two drill bits.

- Sawdust pusher to move sawdust to one end of CNC

- Safety Photo eyes

- Does come with blowpipe for dust ventilation. Can be plumbed to baghouse.

- Software is Cambium. We created machine files in Cadwork to upload into Cambium.

- There is a rollcase on the CNC bed, although it was never activated at DRJ.

- This piece of equipment is complete and does come with some spare parts, mills, blades, chain, etc.

BAGHOUSE

- 32,000 ACFM baghouse

- Complete with significant blow-pipe, motors, dust collection bags, etc.

- The blow-pipe does have a fire-suppression system which will likely have to be installed by a certified fire suppression system installer.

CLT SANDER

- SATOS-32K Dual head sander.

- Sands both the top and the bottom.

- Sanding heads do oscillate back and forth to prevent “clogging” of the sandpaper

- Automatically feed

- Automatic sanding thickness settings

- Sandpaper removal/installation tool

- Blowpipe for dust collection

- Approximately 45’ of Infeed and outfeed roll cases

- This piece of equipment is complete and does come with spare sandpaper of various grits.

For more information contact Shawn Westbrooks at shawnw@drjlumber.com or 541.643.8918.